meet

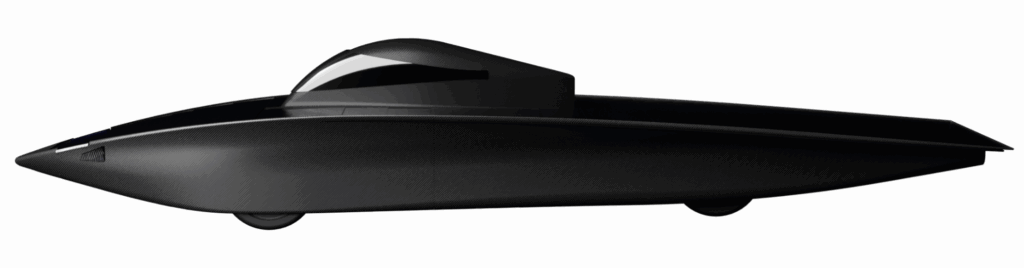

lux025

Create. Evolve. Thrive.

This was the mantra of our season. With a clear vision in mind, we set out to develop lux025, a solar vehicle designed to push the boundaries of modern engineering. Our ambition was to reach for excellence in the way we always have.

A diverse team formed with specializations in electrical engineering, management, mechanical engineering, and computer science. Together, we’ve built a car that goes to the limit of efficiency. After countless hours in the workshop, lux025 was ready to face its ultimate challenge: the Bridgestone World Solar Challenge.Over the course of 3,000 kilometers of competition, our car was driven along the vast highways of the Australian Outback, competing against student teams from across the world.

Returning home, we carried with us a deep sense of pride and lasting memories from an intense season after competing over 3,000 kilometers on the highways of the Australian Outback- more than 14,000 kilometers away from our home in Munich. Lux025 is the pride of over 80 interdisciplinary students, who poured their heart and passion into the car.

Welcome to the future of driving and solar mobility.

This is lux025.

Key Data

Weight

0

kg

Covered front wheels:

- All three wheels covered for the second time in the history of TUfast.

Top speed

0

km/h

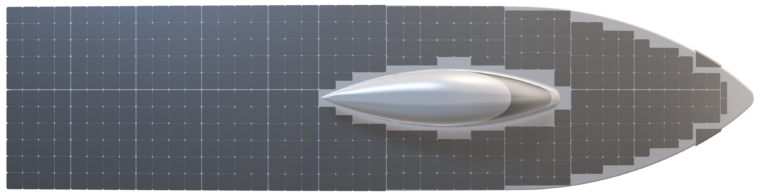

Maximum Solar Output:

- 1500 W

Drag coefficient

0

Length:

- 5600 mm

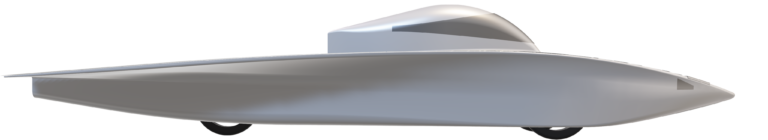

Vehicle Body

Weight of vehicle body

0

kg

Aerodynamic Shape:

- Optimization of the vehicle’s aerodynamics through numerous iterative simulations.

- Use of new innovative technology: Adjoint-Optimization.

Carbon Fiber Monocoque:

- Layer optimization and a layup consisting of different prepregs to maximize stiffness while minimizing weight.

- Total Monocoque weight of only 45 kg.

- Optimization of outer shape for solar cell orientation to maximize harvested solar energy

Drag coefficient

0

High-Tech Materials:

- Use of state-of-the-art carbon fiber for the entire body.

- Lowest weight with simultaneously highest stiffness.

Design and Manufacturing:

- Development of a vehicle body optimized for open-road solar racing.

- Carbon body parts manufactured by our team.

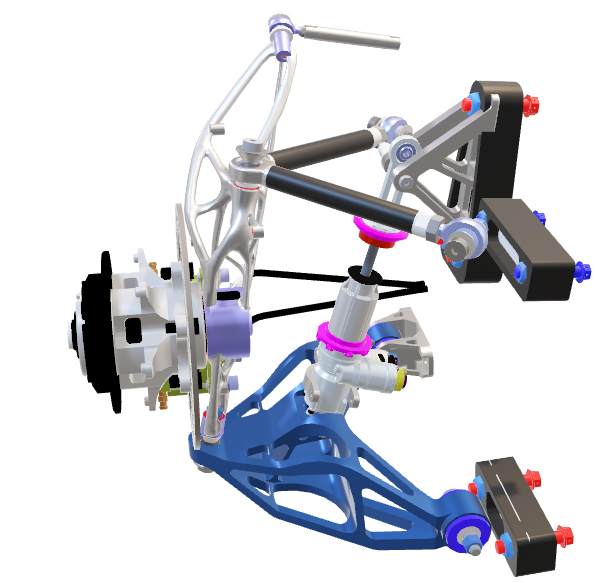

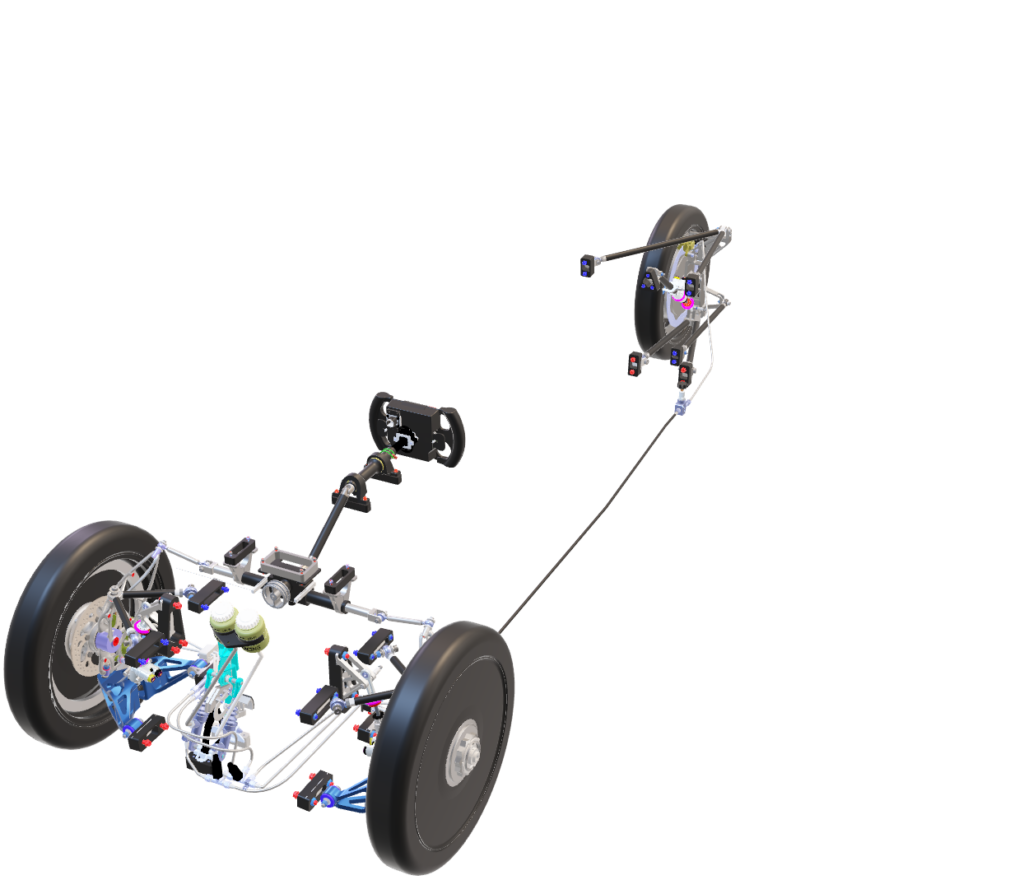

Suspension System

Topology Optimization:

- Uprights, Suspension Mounts and Brake Pedal – varying materials and techniques for different wall thicknesses and part sizes, minimizing weight while maintaining maximum stiffness.

- All components were initially topology-optimized using Altair Inspire to minimize mass and rotational inertia

Suspension:

- Topology-optimized, laser powder bed fusion 3D-printed front upright.

- Front upright reduced from ~11 kg to 0.989 kg.

Drivetrain:

- Titanium front spindle to reduce unsprung mass.

- Top speed: 120 km/h

- Centerlock hubs front and rear for rapid tyre changes during the race

Steering:

- Mechanical active wheel-cover opening system for tight turning radius without compromising aerodynamic performance

Brakes:

- Capable of full stop from 80 km/h in under 30 m.

Our work on topology optimization

Our work on topology optimization

- What is topology optimization?

Topology optimization is a design process that utilizes a feedback loop between itself and stiffness simulations to generate optimal material distribution within a given design space. Its goal is to maximize performance while minimizing material usage, resulting in lightweight and efficient structures. - How do we produce these parts?

These parts are produced through advanced additive manufacturing techniques like 3D printing and selective laser sintering. With these processes, we could create complex geometries with optimized material distribution. - What parts do you have optimized and Sintered in your car?

In our car, we have optimized and sintered the uprights, suspension mounts, brake pedal, and more. - What materials do you use when metal sintering?

These components have been designed using varying materials and techniques accounting for wall thicknesses and part sizes as well as weight saving opportunities, ultimately reducing weight while maintaining stiffness. - What was the weight reduction acchieved with the processes used compared to traditional manufacturing techniques?

The weight reduction achieved through these processes is significant. In the suspension metal mounts, we’ve achieved a reduction of more than 40%, while the brake pedal has seen a remarkable 70% reduction in weight. This improvement represents approximately a 3kg reduction compared to traditional manufacturing techniques.

Driving Strategy

Solar Energy Modeling:

- Estimates solar energy input based on geographic location and time of day

- Provides a consistent energy model for simulation and optimization

Route And Terrain Analysis:

- Processes Australian race routes from GPX data

- Computes distances, curvature, and smoothed road gradients from elevation data

- Captures terrain effects that influence energy consumption

Optimized Driving Strategy:

- Computes an optimized acceleration profile using solar and route data

- Use of Alpso and ParOpt-optimization algorithms

From Sunlight to Speed: Optimized Driving Strategies for Solar Cars

From Sunlight to Speed: Optimized Driving Strategies for Solar Cars

Do you have an electric car that can charge itself from solar panels, but you do not know how to achieve the best possible performance? That is where the Driving Strategy comes into play. By utilizing our own developed pipeline, we can estimate an efficient plan for the race. In other words, what velocity and acceleration should the car have at the moment, considering external and internal factors that influence the solar car? We also account for different scenarios where the reality differs from the conditions we used in the software pipeline earlier. For instance, it may happen that the energy income from the solar panels is 15% higher than we estimated. Consequently, we can consume more energy from the car battery without draining it.