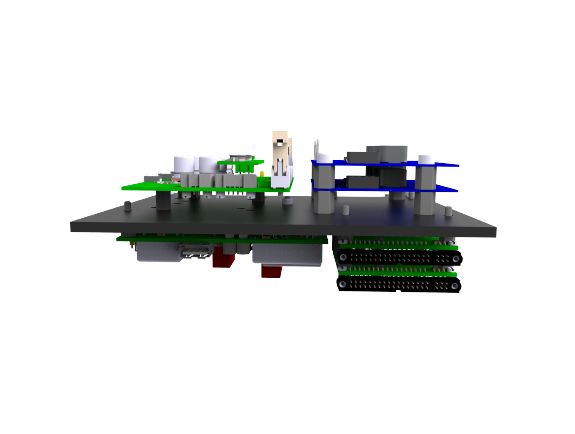

OUR VEHICLE FROM 2015

So far it has participated at the EducEco Challenge in Colomiers, France and the Shell Eco-marathon Europe. It has shown its reliability and efficiency at both competitions successfully. At the EducEco it finished all test and competition runs and at the Shell Eco-marathon it finished all test and 3 out of 4 competition runs.

eLi15 was modified for the EducEco competition due to differences in the regulations. At the EducEco the battery of eLi15 was supported by silicon solar panels, while we used Gallium-Arsenic at the Shell Eco-marathon. Even the motor controller was different. We tuned our motor controller from the previous seasons for the EducEco and developed our own for the Shell Eco-marathon.